P-3 Orion Parts

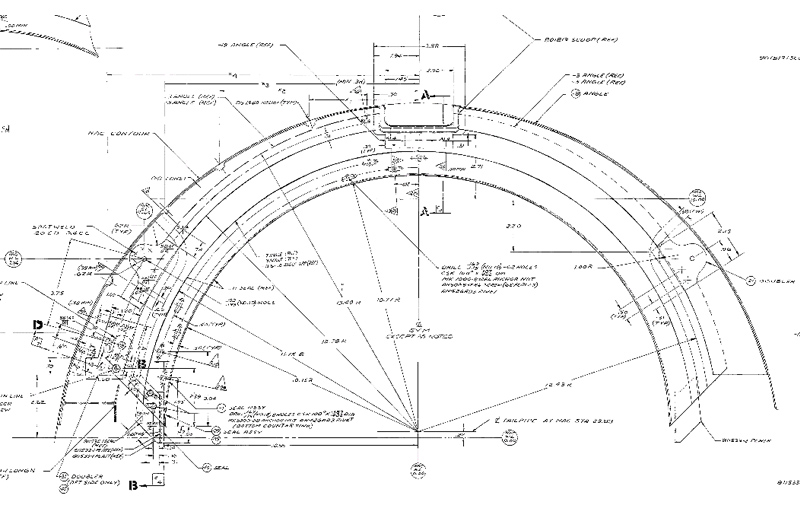

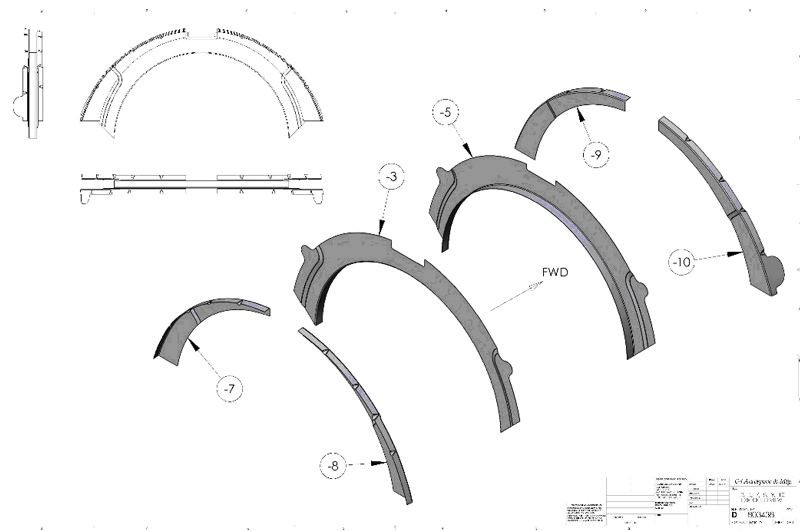

P-3 Orion Nacelle Former Assembly

Description of nacelle former assembly Upper image is a detail from the OEM drawing of an engine nacelle former assembly on a P-3 Orion. The lower image shows the CAD models of the main sheet metal components created in SolidWorks using the OEM drawing. The CAD models were used to create CNC programs for machining form dies to make the sheet metal parts from 2024 aluminum sheet. Full-size drawings of the individual parts were printed on mylar stock for use as inspection aids.

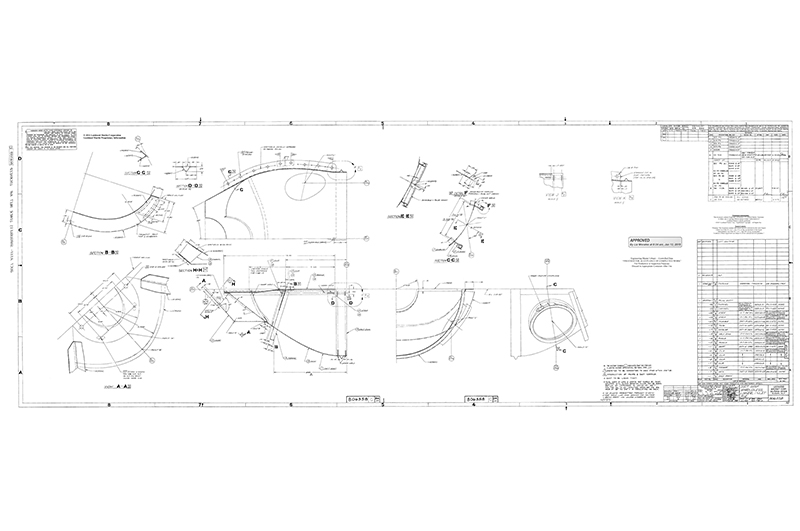

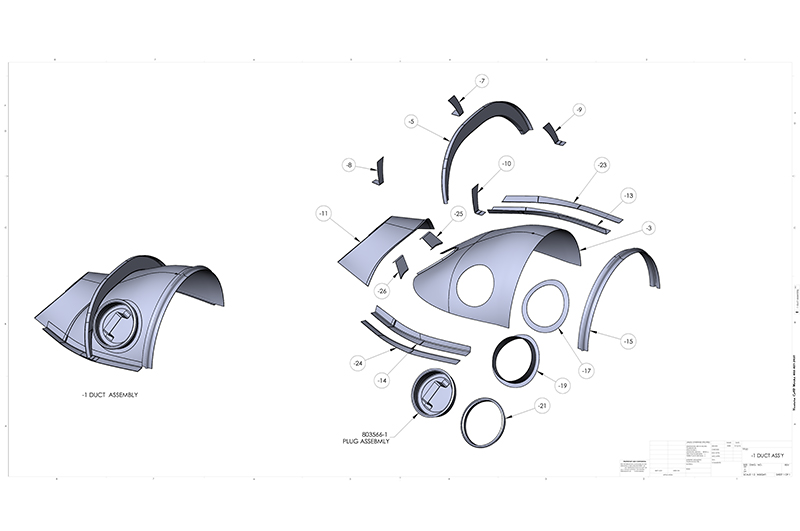

P-3 Orion Lower Inlet Duct Assembly

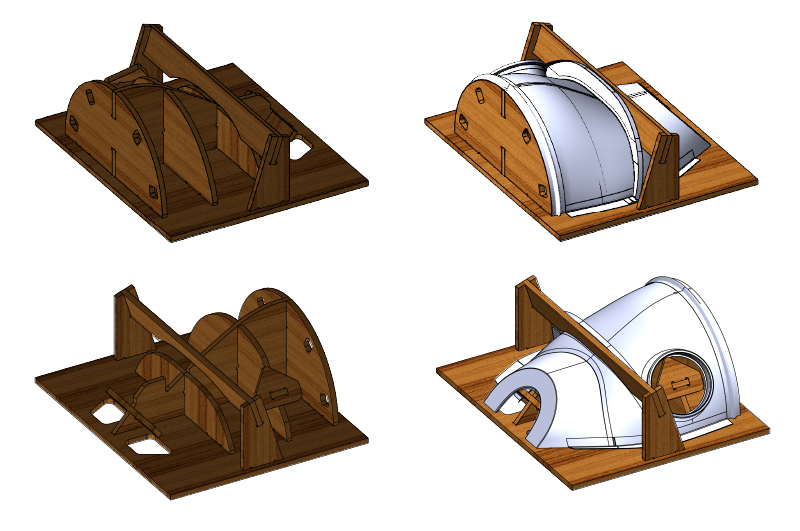

This is part of the inlet duct for the outboard engine installation on a P-3 Orion. The client-supplied OEM drawing and duct loft data was used with SolidWorks CAD software to create part models for this sub-assembly. These part models were then used to create stretch-form and hydroform tooling to shape the parts from alloy 347 and 17-7 PH stainless sheet. The formed pieces were trimmed with a 5-axis laser. A wooden fixture was designed to locate the pieces properly so they could be tacked together using TIG welding before being welded together completely by the process of resistance seam welding. The wood fixture pieces were cut from laminated die-stock using a CO2 cutting laser and glued together.

P-3 Lower Inlet Duct Assembly Drawing

Exploded view created with SolidWorks CAD software using OEM drawing (Shown upside-down for clarity)

Positioning fixture for final assembly of duct parts using resistance seam welding.

Final Part (Shown upside-down for clarity)