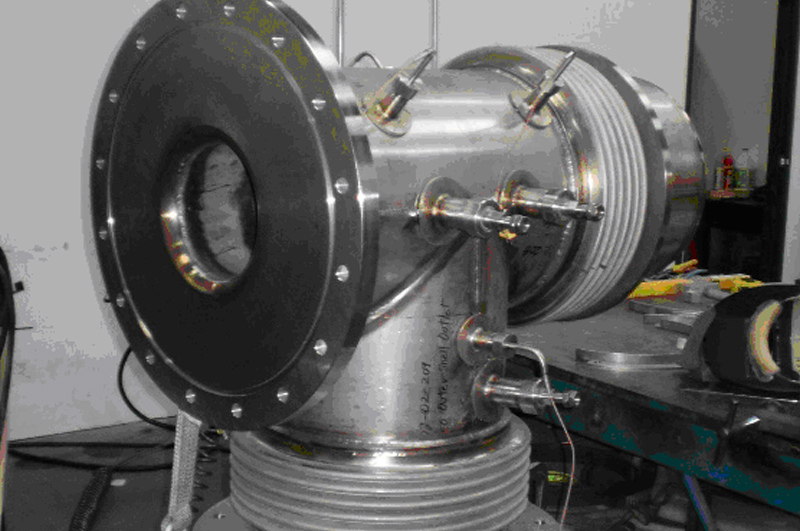

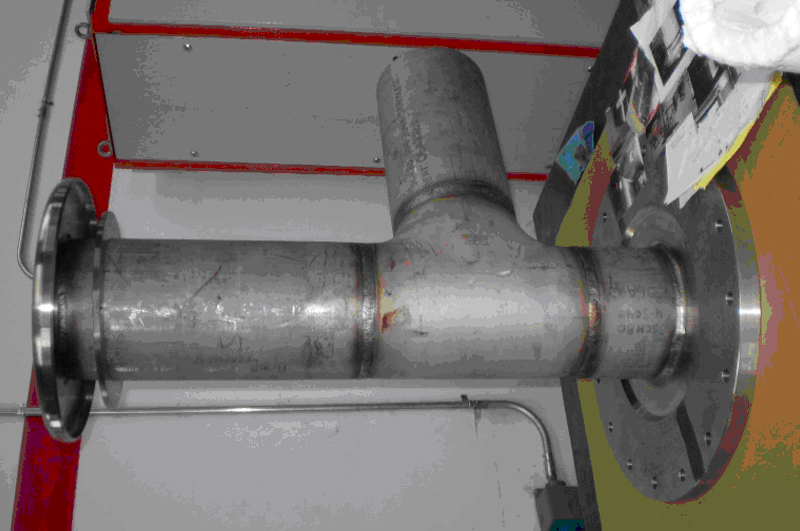

"T" Assembly

"T" Assembly

This “T” fitting is used in the smelting of titanium. The basic process involves heating the raw ore in a vacuum furnace until it becomes a gas. The gaseous titanium (and impurities) are drawn off and pass through an electro-static filter that collects the impurities. The purified titanium gas is then allowed to coalesce into a solid but porous “sponge”, which can then be re-melted and formed into a solid billet. This “T” sits on top of the furnace. The stainless steel inner pipe (top right) is surrounded by heating elements (lower left), then encased in a stainless steel outer jacket (top left). Because of the vacuum inside the inner pipe and the high temperature that is required to be maintained, the inner pipe runs red-hot and near the melting point of the stainless. To eliminate the pressure differential and premature failure of the inner pipe, the space between the inner pipe and outer jacket is also under vacuum. Both the inner pipe and outer jacket must be leak-proof. Stainless bellows allow for expansion and contraction of the assembly between operation cycles. I was responsible for fabricating several prototypes, converting the Japanese metric OEM assembly drawings into individual part drawings with imperial dimensions and standard English notations, sourcing vendors for machining the larger parts, and final assembly. Ultimately, I produced several shop manuals that were utilized by the shop staff when a production contract was awarded.